Words & Design by Mike Barker

At this moment around the world thousands of people are playing and building with LEGO. In the hands of children and adults, various elements are being locked together in an infinite variety of ways to create wonders only hampered by the builder’s imagination.

The brick can shape anything from flying creations and strange creatures of a child’s imagination, to intricate models created by adult fans or thought-provoking works of art. And this is due to the genius and simplicity of the tube-and-stud mechanism that gives the LEGO brick its’ clutch power. The brick both creates a constrained world in which to build in and opens the imagination to push those boundaries. As organic and fluid the artworks of Nathan Samaya may be, the shape of the brick is still visible as if his sculptures are pixelated versions.

From the simplicity of the brick, the company created a ’system of play’ which introduced into the market a range of interconnected products when the toy industry was based on standalone toys. Here’s one range of products spanning decades that continue to interconnect. With every new LEGO set someone purchases, their ability to build grows, because the sum of those parts can make something wholly new. It is even said bricks from 1958 will still snap together with new bricks bought today.

LEGO elements have been made since 1949

average number of LEGO bricks per person

LEGO bricks were sold in 2015

bricks stacked in a single column would

reach all the way to the moon

With other toy brands children might mix the play with toys from one range and another, Hasbro G.I Joe’s driving Mattel Barbie vehicles, Hot Wheels daring to share the road with Matchbox cars. But for LEGO, every product they sells can fit, literally, together with other previous products. Fashion and pop culture have changed the look of Barbie and G.I. Joe over time, and the same can be said about LEGO sets.

Once again the largest toy maker in the world, LEGO has reached this spot based around one singular product. It reclaimed the crown in late 2015 from toy giant Mattel. Over a decade ago LEGO was nearly in trouble, and its’ revival and further growth has been a result of focusing on the brick. Amazingly LEGO has barely tapped the South American and Chinese markets, while new themes continue to grow the base European and North American markets.

While other toy makers, like second and third place Mattel and Hasbro, own multiple brands and continue to create new ones, LEGO is all about the brick. If rumours are true, Mattel and Hasbro are working a plan to claim the number one spot together through a possible merger. But to label the entire range of LEGO products as construction toys understates the power of the system. Every set and product line is built off the brick. When LEGO launched it’s board games line, the games were buildable (but not only about the brick).

The LEGO we know today began life as a very different company. There were many years before the family run toy maker created the first plastic brick which paved the way to becoming a global success.

Wooden years

Before the brick

The story of the brick begins several decades before that first simple plastic stacking brick was created. Like any history, there are events that shaped the brick in the years leading to the perfect circumstances that were ripe for the LEGO we know now to exist. Those early decades shaped the company through the successes and numerous setbacks, events that created a better quality brick that’s stood the test of time.

There are clues in their products to the company’s founding, clues possibly only noticed by the most observant LEGO fan. Over years a few models have featured as an architectural detail the number 1932, whether on a fire station or a LEGO store in the recent town square set. While that is the year a lone Danish carpenter began making toys, it’s not even the year the company got it’s name or the point in history when the plastic bricks started flowing. And though 1932 remains a pivotal date in this story, that carpenter’s story started many years before.

Ole Kirk Christiansen was already a skilled carpenter when in 1916 he purchased a small woodworking shop in Billund, Denmark. The firm had already been making handcrafted furniture and helping construct homes in the rural Jutland farming region for two decades when Ole took ownership.

Business was good but Ole was to face his first of many setbacks in 1924 when the workshop and the Christiansen family home burned down. This was the first of three fires that would shape the course of the company. The prospect of good trading and a bright future allowed Ole to rebuild an even bigger workshop. Of course trial by fire was not the only challenge Ole overcame in years before Lego.

The onset of the Great Depression saw the need for the firm's carpentry skills diminish, and required Ole to lay off his entire staff. Far worse in 1932 Ole lost his wife, leaving him to take care of his four sons. Inspired by a toy he made his children, Ole saw an opportunity, and need to put food on the table, he began making wooden toys and other small household items.

Those first few years were a struggle for the one-man operation, though Ole was helped out by his son Godtfred. At first sales were slow but word spread of his well-made toys and attracted some sales. Times were still tough for the business, and when the bankruptcy of a department store meant its’ large order would go unsold Ole found himself personally selling his toys to shops throughout Denmark, often being paid in food.

By 1934 the business had begun to pick up, and Ole had been able to hire back many of his former employees. Ole began to see a future in the toy business with his line of wooden toys. He felt they needed a good name, short and meaningful to represent the new toy company. While Ole had his two favourite names, he held a contest with his employees, but in the end chose one of his names. Combining the Danish words ‘Leg got’, which translates as ‘play well’, The name LEGO was now established. According to LEGO Group history it was only discovered long after that lego is latin for ‘I put together’. Fitting when you learn how the brick came to be.

LEGO Leg godt Play well

With the name established, the business grew throughout the 1930s. Ole had insisted on using the highest quality of materials to make the toys, and not cutting corners which he saw as cheating his customers. One early toy the company made were the popular yo-yos, but their popularity was short-lived, leaving the company with surplus product. However Ole wasn’t wasteful, the yo-yos were cut apart and became wheels used on other toys. He also invested profits wisely, purchasing a milling machine to speed up production and more importantly improve quality.

One story goes that Godtfred came to his father to boost that he’d saved the company money by lacquering a shipment of toys only two times instead of three. Ole was not only displeased with the inferior craftsmanship, he made Godtfred get the toys back and complete the third coating. Once done the work, Ole explained to his son the importance of only the best was good enough for their customers. The lesson gave birth to the company’s slogan, “only the best is good enough”.

As the 1930s came to an end the company was making a profit, but the 1940s brought the next setback for LEGO. 1940 saw the occupation of Denmark by Germany. In the winter of 1942, an electrical short started a fire in the workshop, destroying the building the models and all the drawings.

LEGO would rebuild quickly with a new and larger factory for the nearly 40 employees now making wooden toys. After the war ended, on a trip to Copenhagen Ole saw a new machine that would usher in a new era for LEGO. The purchase of the company’s first plastic moulding machine would eventually lead to brick we now know.

Plastic years

Birth of the brick

Today we take for granted how commonplace plastic is in our lives, but in the 1940s plastic was still slowly growing in adoption. Making plastic and moulding the material into shape would go through decades of trial and error before a suitable injection moulding machine would come onto the market. The Second World War accelerated the improvement and manufacture of presses, so as life got back to normal, plastic began to dominate in this new peacetime world. LEGO would embrace this change with its’ typical eye for quality.

On a trip to Copenhagen to look at new production machinery, Ole was drawn to this new injection moulding machine. Like years before Ole could that such a machine would raise the quality of his products. It’s curious for a skilled carpenter with decades of experience shaping wood to see the potential if not the demise of wooden toys. So it was that LEGO became the first company in Denmark to own a plastic injection moulding machine, at a cost of DKK 30,000, which at the time was nearly all of the previous years’ profit.

In those first years the moulding press made small plastic bears and rattles before LEGO made it’s first popular plastic toy, the Ferguson tractor. The English made grownup version was popular with farmers across Europe, so the LEGO toy meant children could have their own one to play with. It even came as a box of parts that children put together.

At the same time Ole worked to improve the design of a simple sample brick he’d picked up at that trade show in Copenhagen. In 1949 LEGO began to market a line of automatic binding bricks in four and eight stud variations. By 1953 the bricks were being sold as LEGO Mursten (or LEGO Bricks) and for the first time the LEGO name began appearing stamped inside each brick.

With a growing product line featuring wooden and plastic toys, it fell on Godtfred to make sales trips, travelling further from their Danish base. On a ferry journey returning from England Godtfred had a chance encounter with the head of a large shopping centre, and a conversation that would ultimately shape the company profoundly. Their conversation around the state of the toy industry would lead to discussion around the lack of a system or cohesion across product lines. Such a concept may seem normal today but toys in those days were one off products that didn’t fit together, or have much expandability. (Both Barbie and G.I. Joe were still years away.)

The conversation stuck and soon LEGO established its’ System of Play. Products worked together so that each set revolved around a bigger theme, starting with the town plan. The bricks and other elements fit along side plastic vehicles and accessories. Soon LEGO began selling numerous sets, including small expansion packs of bricks sold in corner shops. While each set fit into a town setting when assembled, the bricks could be combined into new creations as children saw fit.

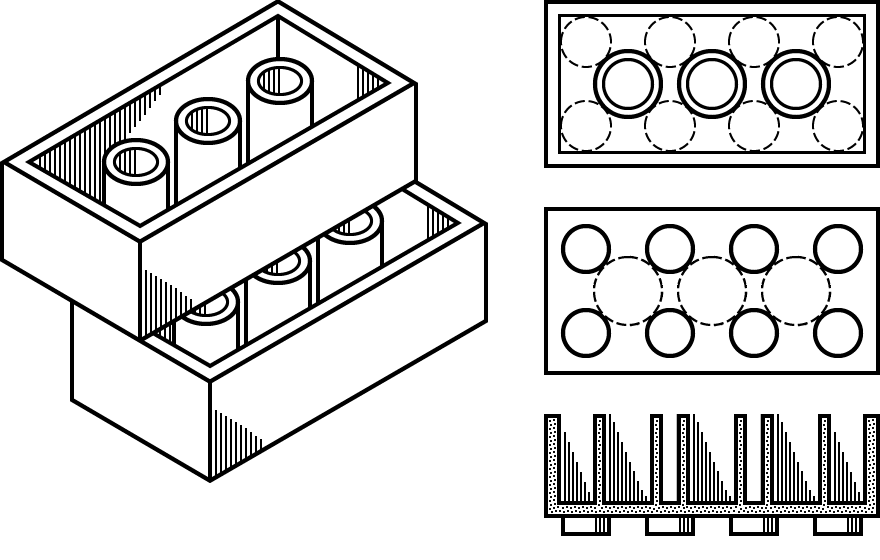

The early bricks had studs and an opening along the end, but they still lacked one feature that was needed to make the product a success. The bricks could be stacked and stayed in place, mostly, but when picked up models would simply fall apart. The brick lacked clutch power, the feature that locked bricks together. Knowing a better quality brick could be made, Godtfred took it upon himself to solve the problem, producing numerous prototypes until he added tubes inside the bricks.

Adding the tubes allowed the bricks to apply pressure not only around the outside of the studs but also a balancing amount between studs. In 1958 the patent was issued for the new brick—existing elements were improved and new ones added, all featuring the new clutch power.

The 60s arrived with another set back for the company, and like before it would prove reshape the company significantly. For the third time a fire would destroy another wood production building. With sales clearly showing a future in plastic, wooden toys were discontinued.

Now with over 450 employees, the company began expanding around the world, selling LEGO bricks across Europe and licensing the brick in North America to luggage manufacturer Samsonite. The range of elements grew, as did the number of sets being made each year. By the end of the decade the workforce had nearly doubled, larger DUPLO bricks were introduced and bricks were being made in the hundreds of millions. The LEGOLAND theme park would also open in 1968 and bring over 600,000 visitors to Billund its’ first year.

The next decade would see the introduction of many new products including the minifig and the Castle and Space themed sets. The Samsonite licensing arrangement ended and LEGO USA is created to expand more fully into North America. The basic blueprint was well established by the 1980s, since then LEGO has continued to expand with new products and themed—including licensed themes—and everything has been designed around the basic brick.

The tube and stud configuration has remained the cornerstone with each new element complimenting and snapping into the elements that have come before. From the hundreds of millions of bricks to billions made each year, there are now over 760 billion LEGO elements.

Today

Making all those bricks

As the number one toy maker with hundreds of popular products requires an efficient supply chain, and it seems befitting for LEGO to have mastered a manufacturing system while maintaining only the best is good enough level of quality with as little waste as possible.

In automated factories around the world, machines work day and night moulding the 3,500 LEGO elements currently in production. Those factories have to run 24 hours a day to keep up with the growing demand for bricks. Just in the Billund factory over 50,000 elements are produced every minute, with a yearly total of 27 billion in 2014. Globally those machines churn out about 117,000 elements a minute.

LEGO elements made every second

different colours are in production

are sold worldwide every second

As Christmas 2015 approached LEGO warned of possible shortages of the bricks needed to fill sets. The launch of the long-awaited new Star Wars movie with multiple LEGO product tie-ins could have scared others, but LEGO was well prepared after 15 years producing Star Wars sets.

The process of making elements begins with raw plastic granulate which is fed from giant waiting silos through vacuum pipes to dozens of moulding machines. Base coloured granulate is combined to achieve the desired colour and heated to 232-C so the plastic is dough like. [Injected into moulds], the plastic dough is press into the mould cavity under great pressure before the machine releases and still hot bricks are allowed to cool and dropped into a waiting bin. Robots retrieve these bins when they’re full and send the bins along conveyors into a completely automated warehouse.

During the moulding process, the plastic dough is fed into the mould through channels. When the press releases the extra plastic left, the flash, is immediately recycled to make more bricks. If you ever made a model, you’ll be familiar with manually releasing parts from the flash.

The moulding process in LEGO factories is so well tuned that only 18 bricks in a million are rejected. Not wanting to throw away any extra plastic, LEGO recycles the material into new elements, creating over 75 million ‘green’ pieces a year.

While LEGO currently has over 3,500 active elements in dozens of colours, there isn’t a dedicated moulding press for each part. Instead the moulds are interchangeable and installed in a waiting injection moulder when needed. The moulds themselves are valuable precision made, complex and heavy tools. They can cost thousands to make so they are well maintained by dedicated staff and lifted and carried around the factory with great care.

Some elements get a bit more attention after they are pressed. For example all the minifig elements need to be finished and assembled. Blank heads receive their expressions while the torso, legs and many accessories get their graphics printed on. The hands are inserted into arms that get inserted into the torso. And again, all through a finely-tuned automated process.

When the various elements are needed for packaging in sets, the robots retrieve the bins from the warehouse and bring them to a whole chain of automated machines that separate and count the necessary elements required for each bag within the set. Packaged, boxed and on their way to stores around the world, the process is continuously moving.

There are still plenty of humans involved in manufacturing LEGO elements, with workers changing or carrying out maintenance on the injection moulds, technicians continuously measuring bricks for quality and precision. Someone is even needed to change and adjust the colours as the moulding press switches from printing one colour to another. During the change over the machine processes multi-coloured bricks which are also recycled to reduce waste. The machines may do a lot of the repetitive work, but the factory workers have the important job of making sure only the best bricks are good enough to reach customers.

Did you know?

LEGO is the world’s largest tire manufacturer

Last year LEGO made over 675 million tires, making LEGO not just the top toymaker but also the number one tire manufacturer. In 2014 LEGO made more than 650 million LEGO tires, a large increase from previous years that saw nearly 400 million tires produced annually. LEGO is not only first, they made more tires than the top three automotive tire manufacturers combined. Number two manufacturer Bridgestone makes around 190 million a year, Michelin is third with 184 million, and Goodyear fourth with 180 million.

LEGO first started making rubber tires for the LEGO system in 1962. Their tires may not be rated for asphalt, and traditional tire manufacturers probably use far more rubber, but the sheer number produced is another indicator of the scale of LEGO.

5 billion and growing

First LEGO mini figure is introduced

minifigs were made in 2015

minifigs were made per second in 2015

Included in LEGO sets for over 35 years, the mini-figure (or mini-fig) completed the system of play and brought the themes to life with characters dressed up for medieval battles, flights to the moon or driving around the LEGO town. Made from three parts and extended with numerous accessories, the minifig not only fits into the system but makes up it's own interchangable world. And there are a lot of them. In 2014, LEGO reported that half a billion mini-figures joined a population already over 5 billion.

First launched in 1978, the minifigs has become the mainstay of nearly every LEGO themed set. Prior to this LEGO had an armless figure with no facial features or moveable legs. The persistent smile appeared on a police officer first in the Town theme before quickly being added to the Castle and Space themed. Two months after the first male minifigs, a female nurse was added to the line by the introduction of a hair piece.

The basic minifig stands exactly four bricks tall with the ability to snap onto any stud standing or sitting, and topped with a single standard-sized stud. For 24 years minifigs all came in the same height, then in 2002 LEGO introduced part number 41879 (Legs short) and soon after new sets from Harry Potter to Star Wars Emoks and Lord of the Rings hobbits could appear shorter.

On the mining’s 25th birthday in 2003 LEGO not only announced that 3.7 billion figs had been created, but for the first time minifigs appeared with natural skin tones for basketball themed sets. The following year saw the characters from Harry Potter in LEGO form with natural skin tones, and soon after the Star Wars sets were updated as well.

In 2010 the first series of Minifigures collectables was launched. Each series since has featured everyday, historical, and fantasy characters, as well as two series of The Simpsons and one tying into the LEGO Movie. There were an estimated 3655 different minifigs produced by 2010, with over 300 new characters introduced that year alone.

Between 2006-2009 LEGO was reporting a minifig population of 4 billion, roughly the human population when the fig was first introduced. LEGO also pegged the annual rate of growth just over 100,000. That number increased to 500 million new minifigs in 2014 alone, bring the total population to ‘more than 5 billion’ according to the LEGO Group. Even if this annual rate doesn’t increase further, the minifig population will over take the human population by 2019, if not sooner (and maybe just in time to turn 40).